Case Study

Case Study

Schmancy partners with Zerocircle to lead shift towards algae-based coatings

Schmancy partners with Zerocircle to lead shift towards algae-based coatings

Overview

Overview

Schmancy Pack Pvt. Ltd. is one of India’s leading packaging converters, known for its design-forward, sustainability-driven solutions for cafés, bakeries, restaurants, and lifestyle brands. As demand accelerates for safe, microplastic-free packaging, Schmancy has been actively transitioning its portfolio toward next-generation materials that meet global compliance standards without compromising performance.

Schmancy Pack Pvt. Ltd. is one of India’s leading packaging converters, known for its design-forward, sustainability-driven solutions for cafés, bakeries, restaurants, and lifestyle brands. As demand accelerates for safe, microplastic-free packaging, Schmancy has been actively transitioning its portfolio toward next-generation materials that meet global compliance standards without compromising performance.

The problem

The problem

Schmancy’s coated-paper packaging line depended on conventional plastic or synthetic coatings to deliver moisture and grease resistance. While effective, these coatings created a growing set of challenges: they made packaging non-compostable, introduced PFAs and microplastic concerns, and placed Schmancy under increasing regulatory and customer pressure to shift away from fossil-derived materials. The company needed a high-performance alternative that could replace plastic coatings without disrupting quality, printability, or production throughput.

Schmancy’s coated-paper packaging line depended on conventional plastic or synthetic coatings to deliver moisture and grease resistance. While effective, these coatings created a growing set of challenges: they made packaging non-compostable, introduced PFAs and microplastic concerns, and placed Schmancy under increasing regulatory and customer pressure to shift away from fossil-derived materials. The company needed a high-performance alternative that could replace plastic coatings without disrupting quality, printability, or production throughput.

The solution

The solution

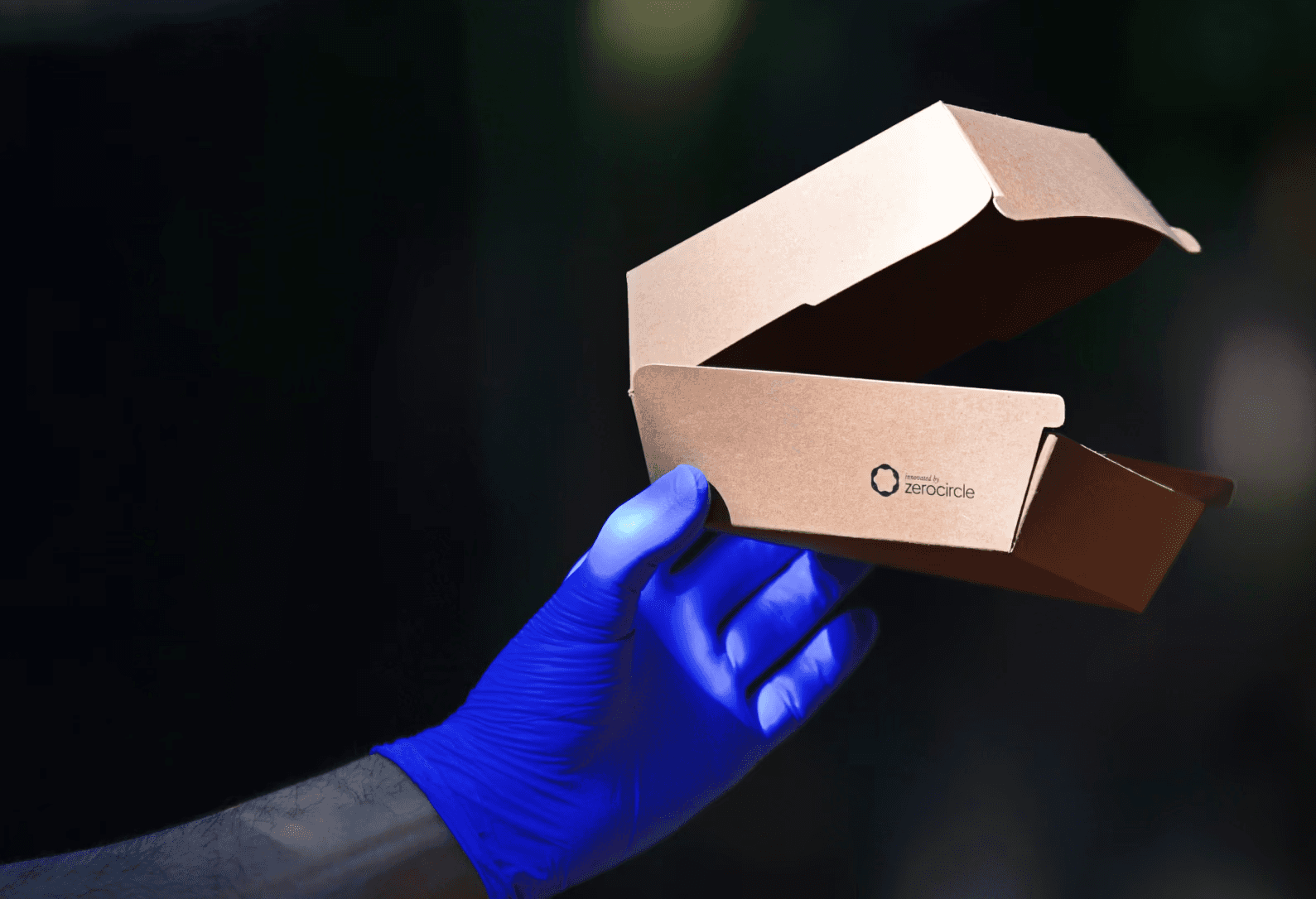

Zerocircle partnered with Schmancy to integrate its seaweed-based coated paperboard — a marine-safe, home-compostable, PFAs-free barrier designed for seamless use on existing converting lines. The material matches the barrier performance of traditional plastic coatings, ensuring durability, food safety, and shelf-life integrity. Zerocircle initiated the partnership with a 100 kg pilot batch, converted into food boxes and trays for early customer validation. A 100 kg batch typically yields 2,500–3,000 medium-sized boxes depending on GSM and dimensions.

Zerocircle partnered with Schmancy to integrate its seaweed-based coated paperboard — a marine-safe, home-compostable, PFAs-free barrier designed for seamless use on existing converting lines. The material matches the barrier performance of traditional plastic coatings, ensuring durability, food safety, and shelf-life integrity. Zerocircle initiated the partnership with a 100 kg pilot batch, converted into food boxes and trays for early customer validation. A 100 kg batch typically yields 2,500–3,000 medium-sized boxes depending on GSM and dimensions.

A seamless shift from plastic-coated paperboard to a PFAs-free, microplastic-free seaweed coating — without any change to Schmancy’s existing converting infrastructure.

A seamless shift from plastic-coated paperboard to a PFAs-free, microplastic-free seaweed coating — without any change to Schmancy’s existing converting infrastructure.

Pilot and scale

Pilot and scale

The pilot demonstrated strong converting performance and commercial readiness. Both teams are now scaling toward replacing at least 5 tons of plastic-coated paperboard per month, creating a clear pathway for Schmancy to transition its broader food packaging portfolio to seaweed-based alternatives.

The pilot demonstrated strong converting performance and commercial readiness. Both teams are now scaling toward replacing at least 5 tons of plastic-coated paperboard per month, creating a clear pathway for Schmancy to transition its broader food packaging portfolio to seaweed-based alternatives.

The

Impact

The

Impact

Plastic displacement: Replacing 5 tons of plastic-coated paperboard monthly removes hidden plastics and PFAs from Schmancy’s packaging line.

Circular design: Zerocircle’s coatings run on existing equipment with no new capex or line modifications.

Regulatory alignment: Materials are PFAs-free, microplastic-free, REACH-safe, and SUPD-aligned.

Economic and social value: Seaweed cultivation supports coastal farming communities across India and Southeast Asia.

Brand advantage: Enhances Schmancy’s positioning as a converter delivering premium, compliant, next-generation packaging for global brands.

Plastic displacement: Replacing 5 tons of plastic-coated paperboard monthly removes hidden plastics and PFAs from Schmancy’s packaging line.

Circular design: Zerocircle’s coatings run on existing equipment with no new capex or line modifications.

Regulatory alignment: Materials are PFAs-free, microplastic-free, REACH-safe, and SUPD-aligned.

Economic and social value: Seaweed cultivation supports coastal farming communities across India and Southeast Asia.

Brand advantage: Enhances Schmancy’s positioning as a converter delivering premium, compliant, next-generation packaging for global brands.

“Working with Zerocircle has been collaborative and solution-oriented. The team is responsive, technically sound, and open to iteration, which makes them feel more like a long-term partner than just a supplier.”

Schmancy Pack Pvt. Ltd.